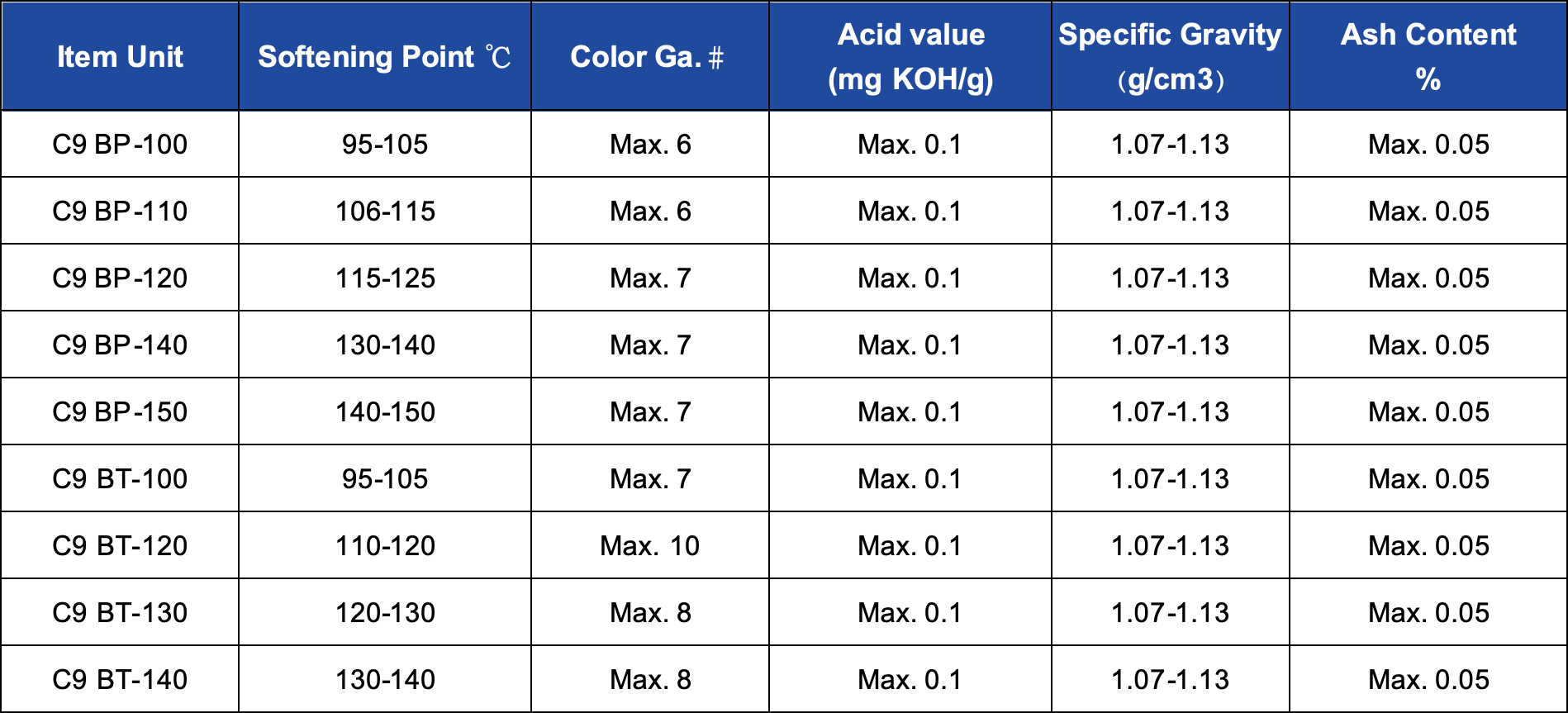

Bitoner® C9 Hydrocarbon Resins are thermoplastic resins with low molecular weight, obtained from polymerizing unsaturated aromatic petroleum feedstock.

They are soluble in most industrial solvents, and particularly in aromatic and aliphatic ones. Wide compatibility with different polymers and resins makes the series excellent multi-purpose products. The major application areas are hot melt adhesive, solvent adhesive, paint, printing ink, and rubber, etc.

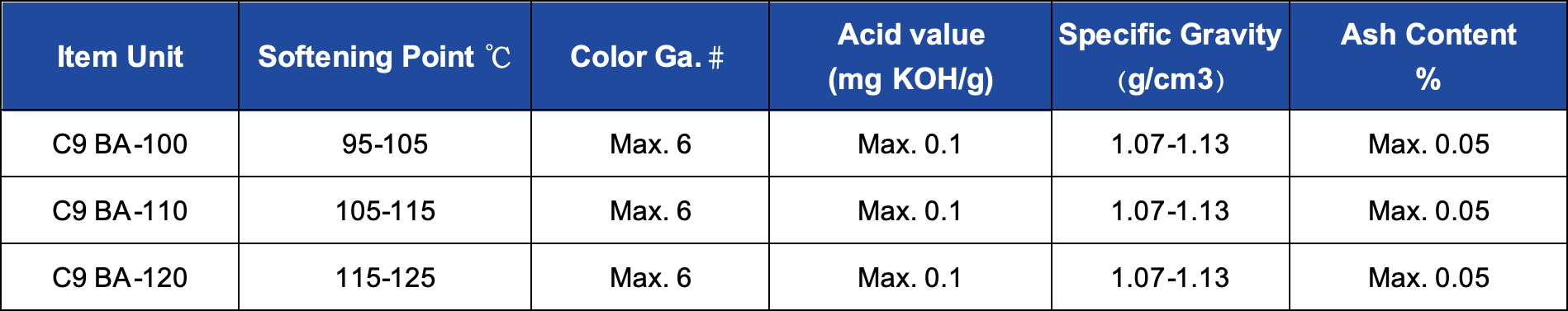

Bitoner® C9 BA series are odor improved grades, specially designed for adhesives application.Characterized by lighter color, very low odor and low VOC,as well as wider compatibility & solubility,they are more suitable for hot melt adhesives,woodworking, packaging, bookbinding, shoes adhesives and contact adhesives, etc.

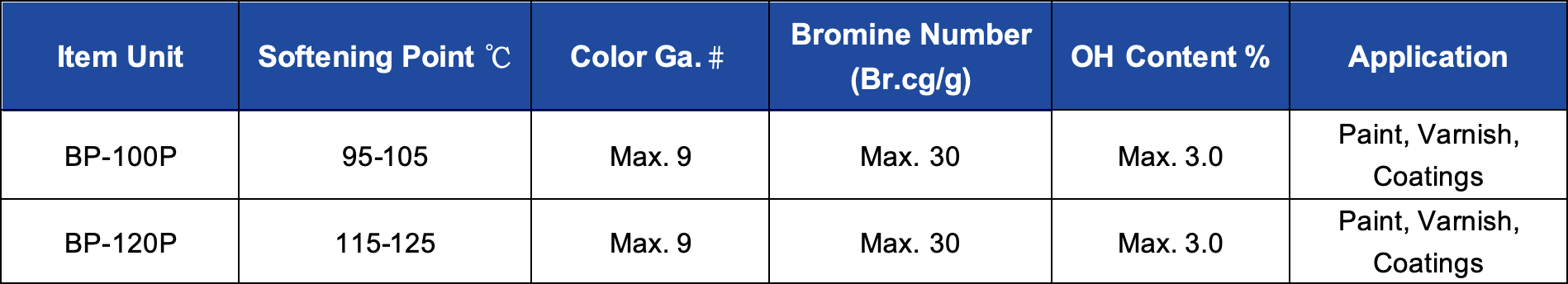

Bitoner® Phenol Modified C9 Resin are pale yellow thermoplastic resins obtained from the copolymerization of aromatic olefin generated in the thermal-cracking process of naphtha.These products are degenerated by phenolic monomers,and contain proper hydroxyl group,which offer excellent compatibility with polymers with high polarity such as epoxy resin,alkyd resin and Ethylene Vinyl Acetate (EVA),and are mainly used as additives for paint and tackifier for Ethylene Vinyl Acetate (EVA) type hot melt adhesive (HMA).

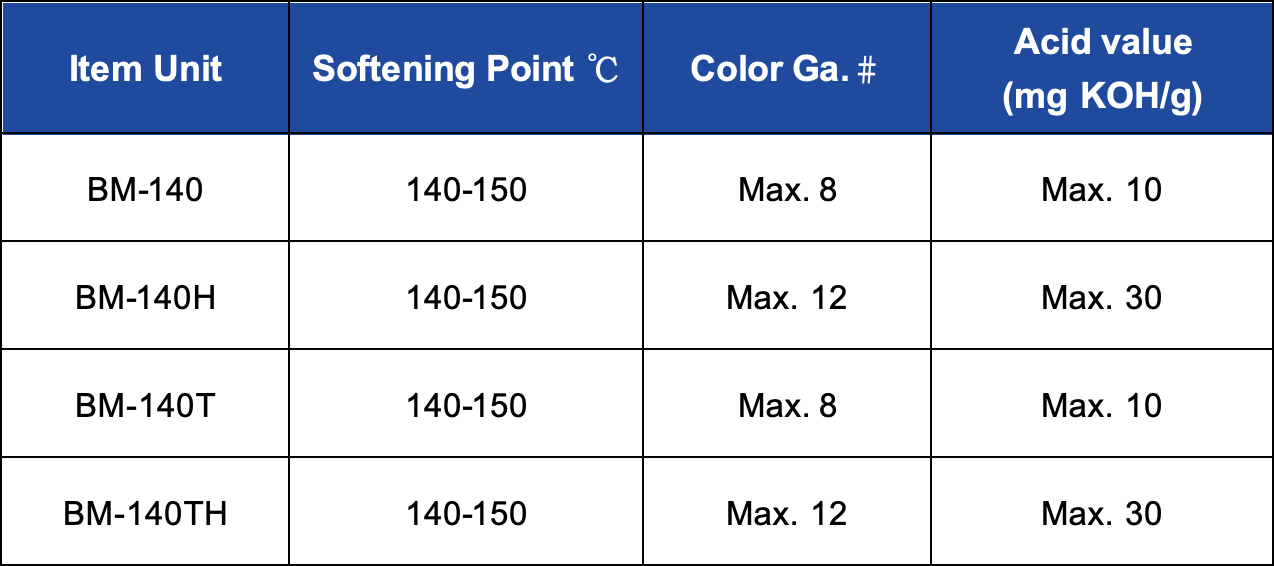

Bitoner® Maleic Anhydride-Modified Hydrocarbon Resin are acid modified thermoplastic hydrocarbon resin manufactured by polymerization of cycloaliphatic-and alkylaromatic monomers.They are heat-reactive, non-toxic and water-repellent.